The Advantages of Our CNC Circular and Slitter Knives Sharpener

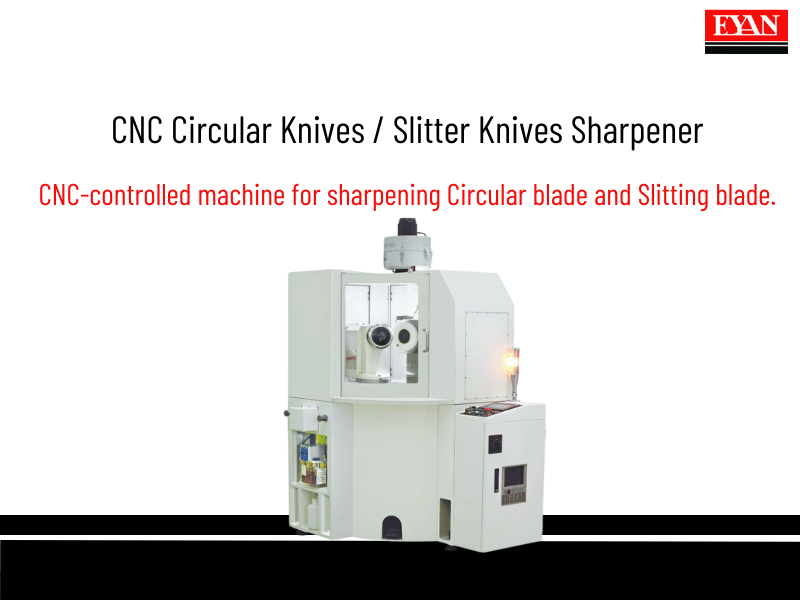

Introduction:

In the manufacturing industry, the precision and efficiency of your cutting tools directly impact production quality and output. Our CNC Circular Knives / Slitter Knives Sharpener is specifically designed to meet these challenges, offering advanced sharpening capabilities that streamline operations across various sectors including paper, textile, metalworking, and food processing.

Versatility and Cutting-Edge Design:

Our sharpener accommodates a broad range of knife sizes, from ψ65mm to ψ500mm. This flexibility ensures that our customers can maintain high standards of precision and efficiency, regardless of the material or industry. Whether you are cutting delicate fabrics or tough metals, our sharpener delivers unmatched accuracy and consistency.

Targeted Industry Applications:

- Paper Industry: Our sharpener is ideal for maintaining the blades used in high-speed paper cutting machines, ensuring clean cuts and minimal downtime.

- Textile Sector: In textiles, where cutting accuracy is crucial, our sharpener ensures that fabric cutting blades are maintained to the highest standards, preventing frayed edges and material waste.

- Metalworking: We support metal fabricators by providing a means to sharpen large diameter circular knives, crucial for cutting metal sheets and components with precision.

- Food Processing: In the food industry, where hygiene and precision are paramount, our sharpener ensures that slicer and dicer blades meet strict sanitation and cut quality standards.

- Tire Manufacturing: For the tire industry, our machine sharpens the circular knives used in cutting and shaping tire components, ensuring smooth edges and consistent quality.

Dual Sharpening Capabilities:

Our CNC Circular Knives / Slitter Knives Sharpener is not just a machine; it's a comprehensive sharpening solution tailored to meet the diverse needs of modern manufacturing landscapes. Its ability to sharpen both circular knives and slitter knives equips it with a unique dual functionality that significantly enhances its utility and efficiency within any production environment.

- Enhanced Versatility: This dual capability allows the machine to serve a wider range of applications, effectively doubling its utility without occupying additional space. Facilities that handle both types of blades — such as those found in the printing, packaging, and metal fabrication industries — can maintain peak operational capacity without the need to invest in separate sharpening systems for each type of blade.

- Streamlined Operations: Integrating dual sharpening functionality streamlines operations by reducing the equipment footprint and simplifying training requirements for operators. With one machine handling multiple types of blades, setup times are minimized, and productivity is maximized. This consolidation also simplifies maintenance and parts inventory, further reducing operational costs.

- Cost-Effective Investment: By eliminating the need for multiple sharpening systems, our machine offers significant cost savings. These savings are not just in terms of initial capital expenditure but also in ongoing costs like maintenance, energy consumption, and operator training. Our sharpening system is designed to deliver maximum functionality while keeping operational costs low, providing an excellent return on investment.

- Improved Quality Control: Having a single, versatile sharpener for different types of blades ensures consistent quality across all sharpening processes. This consistency is crucial for maintaining the precision and effectiveness of the cutting tools, which directly impacts the quality of the final product. Better sharpened blades mean cleaner cuts, less material waste, and reduced tool wear.

- Customizable Sharpening Programs: Our sharpener is equipped with advanced programming capabilities that allow for the customization of sharpening programs according to specific blade requirements. Whether adjusting for blade size, material type, or desired sharpness, our machine can be easily set to provide optimal results for both circular and slitter knives, ensuring that each blade receives the precise treatment it requires.

Innovative Features for Optimal Performance:

We've equipped our sharpener with several innovative features that enhance its performance and user experience:

- High-Efficiency Motors: Developed in-house, these motors maximize performance while reducing energy consumption, aligning with our commitment to sustainability.

- Noise-Reducing Enclosure: Our machines are designed to operate quietly, improving the working environment and complying with safety regulations.

- Electric Operation: By choosing electric mechanisms over traditional hydraulic systems, we offer a cleaner, more energy-efficient, and lower maintenance solution.

Commitment to ESG Principles:

Our dedication to sustainable practices is evident in every aspect of the sharpener’s design. The inclusion of a complete oil recycling system ensures that the oil used in the sharpening process is filtered and reused, minimizing waste and preventing environmental pollution.

Ease of Use and Maintenance:

We understand that in a fast-paced production environment, ease of use is crucial. That’s why our sharpeners are designed with intuitive interfaces and are built for easy access during maintenance. This user-friendly approach reduces downtime and keeps your production line running smoothly.

Conclusion:

Our CNC Circular Knives / Slitter Knives Sharpener is more than just a tool—it's a solution that transforms manufacturing processes. With its advanced features, dual functionality, and commitment to sustainability, it is an essential investment for any business looking to enhance precision and efficiency in their operations.

Call to Action:

Discover how our CNC Sharpener can elevate your production capabilities. Visit our website for more information or contact us directly to schedule a demonstration and see firsthand the difference our technology can make.