OURTECHNOLOGIES

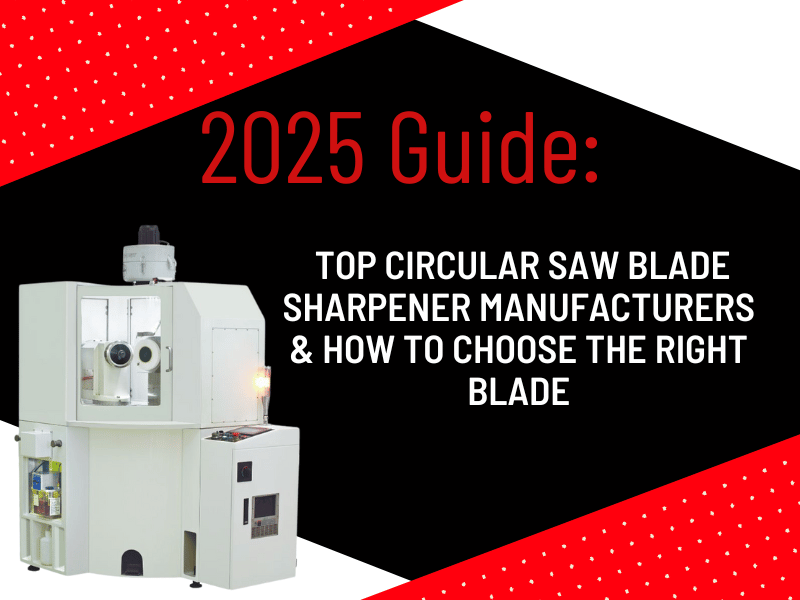

This series is our leading product CNC Circular Saw blade Sharpener Machine (Grinder). This circular saw blade sharpener makes it possible to sharpen HSS and TCT circular saw blade up to 650mm with automatic up and down chamfering function. By entering all the values, the machine will start grinding and chamfering in one process. Neat oil cooling system extends the machine and grinding wheel’s life-span.

Key Features and Benefits

• High-Precision Grinding: Sharpen circular saw blades up to 650mm with exceptional accuracy, ensuring a perfect cut every time.

• Fully Automated Operation: Streamline your workflow with automatic grinding and chamfering in a single process.

• Extended Lifespan: The integrated oil cooling system prevents overheating, prolonging the life of both the machine and the grinding wheel.

• Versatile Applications: Ideal for industries such as metalworking, woodworking, and automotive manufacturing.more

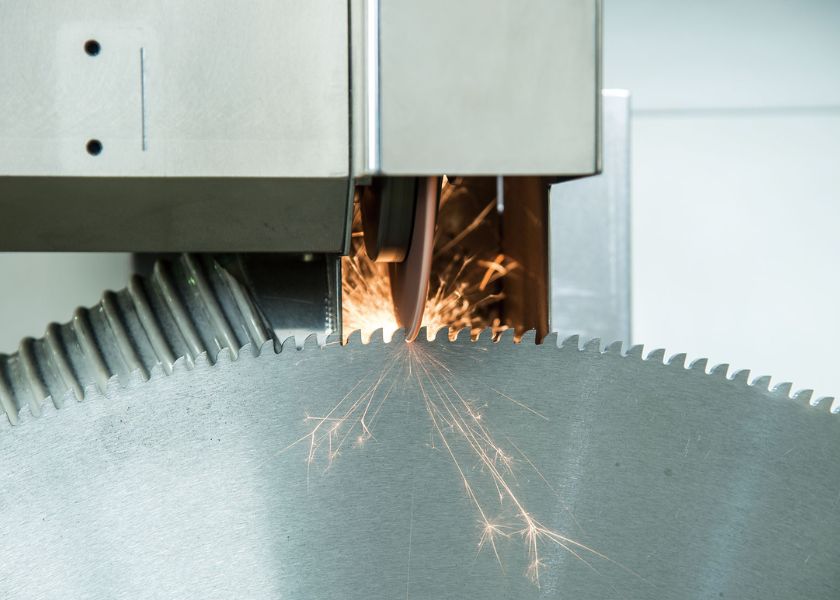

EYAN's CNC Friction Saw Blade Sharpener is a state-of-the-art solution designed for precision and efficiency. Equipped with advanced CNC technology, this sharpener ensures each blade tooth is sharpened to the exact angle and depth, optimizing cutting performance and extending blade life. Its user-friendly interface makes it accessible to operators of all skill levels, while customizable sharpening options provide flexibility for various blade types and applications.

Key Features

• Advanced CNC Control: Guarantees precise sharpening for consistent blade performance.

• Customizable Settings: Adjustable angles and depths to suit various blade types and cutting needs.

• Durable and Reliable: Built with high-quality materials to withstand heavy-duty industrial use.

• User-Friendly Interface: Simplifies operation, making it suitable for both professionals and beginners.

• Eco-Friendly Design: Minimizes energy consumption and reduces waste during sharpening.

Ideal for industries such as steel processing and automotive manufacturing, this sharpener enhances productivity by reducing downtime and sharpening costs. Contact us today to discover how EYAN’s CNC Friction Saw Blade Sharpener can elevate your operations.more

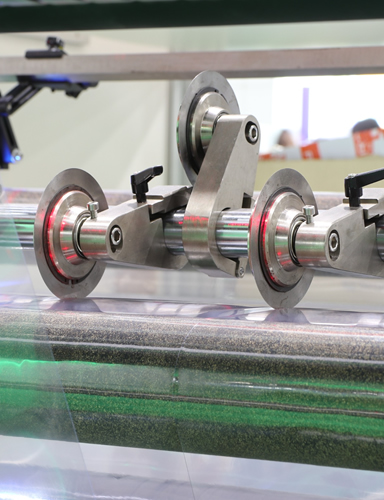

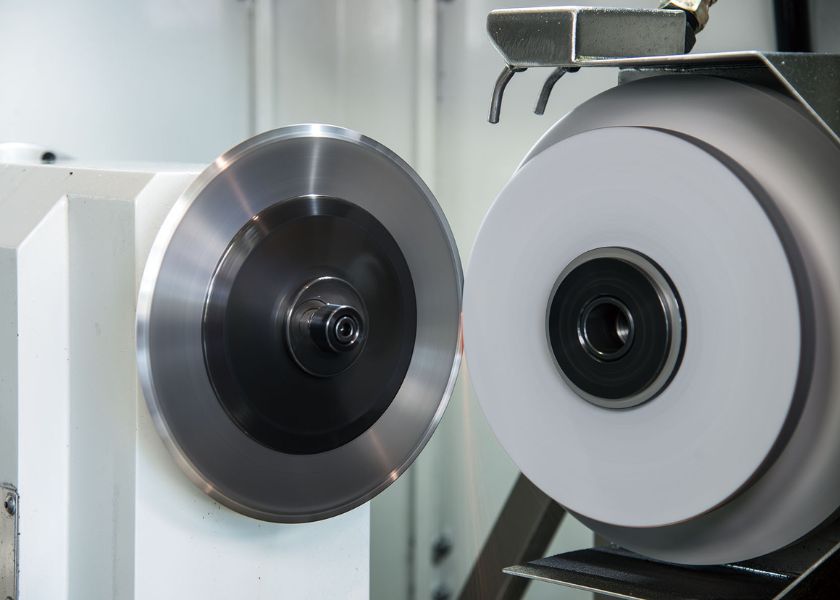

EYAN's CNC Circular Knives & Slitter Knives Sharpener is a high-precision machine designed to meet the sharpening needs of circular and slitter knives across various industries. With advanced CNC technology, this sharpener ensures each knife edge is honed to perfection, delivering sharp, accurate, and durable cutting performance. Its intuitive controls and customizable settings make it an ideal choice for businesses seeking efficiency and reliability.

Key Features

• CNC Precision Technology: Guarantees consistent sharpening angles for superior cutting performance.

• Wide Compatibility: Supports a variety of circular and slitter knife sizes and materials.

• Customizable Sharpening Options: Adjustable angles and depths to meet specific cutting requirements.

• Robust and Durable Design: Engineered for heavy-duty use in industrial environments.

• Easy Operation: User-friendly interface simplifies the sharpening process for all skill levels.

Perfect for industries like paper, packaging, and metal processing, EYAN’s sharpener helps reduce downtime, extend knife lifespan, and ensure consistent cutting quality. Contact us now to learn how this machine can enhance your operations!more

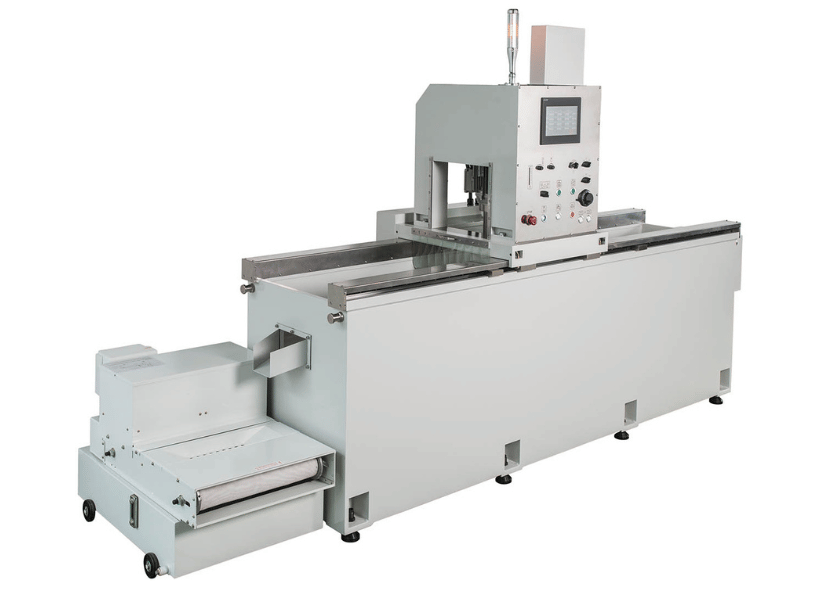

EYAN's CNC Straight Knife Grinder is a cutting-edge solution designed for precision sharpening of straight knives used in a variety of industries. Equipped with advanced CNC technology, this grinder ensures consistent sharpening angles and a flawless edge, enhancing the performance and lifespan of your knives. Its user-friendly design and high-speed operation make it an essential tool for businesses looking to optimize efficiency.

Key Features

• CNC Precision Control: Delivers accurate and consistent sharpening for straight knives of various sizes.

• Customizable Settings: Adjustable angles and parameters to meet specific sharpening requirements.

• Heavy-Duty Construction: Built for durability and reliability in demanding industrial environments.

• Simple Operation: Intuitive interface for easy use, even by operators with minimal experience.

• High Efficiency: Reduces downtime and sharpening costs with fast and precise operation.

Ideal for industries such as woodworking, metalworking, and plastic processing, EYAN’s CNC Straight Knife Grinder ensures your knives are always in top condition for high-quality cutting results. Contact us today to learn more about how this machine can benefit your business!more

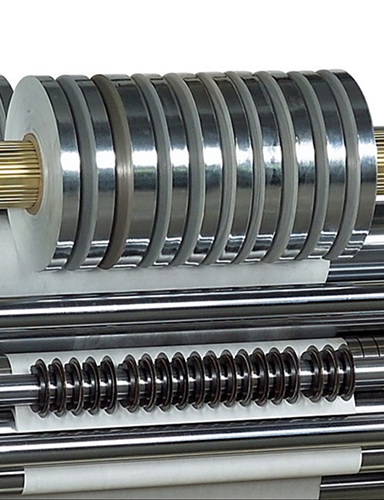

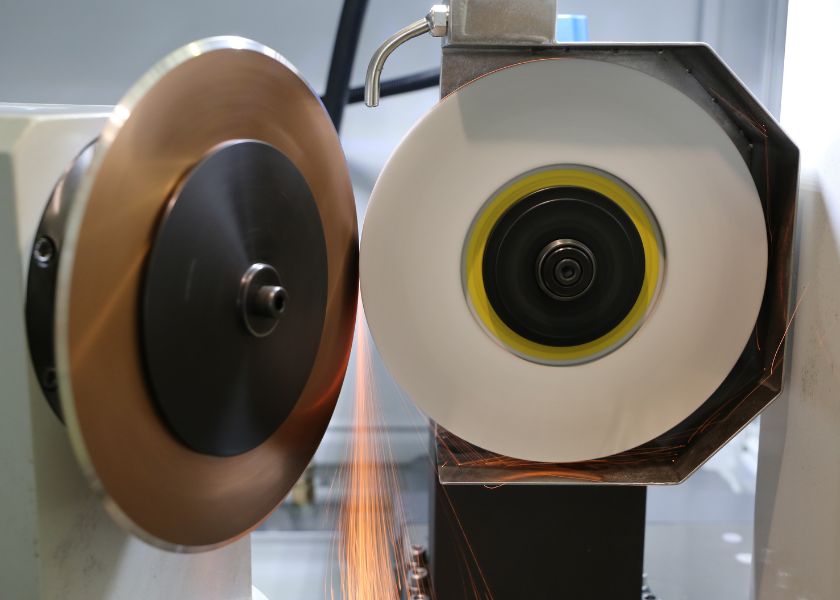

An semi-automatic, environmental machine for grinding circular Knives and Slitting Knives of cutting paper tube, iron tube, electronic tablet, plastic tube, PE tube, rubber, tire, sticker, copper tube. Knife Diameter: ø65 ~ø350 mm. Swivel angle:±45°. Equipped with sliding door, preventing from dangers, cooling fluid spilling out and reducing noise while the machine working. more

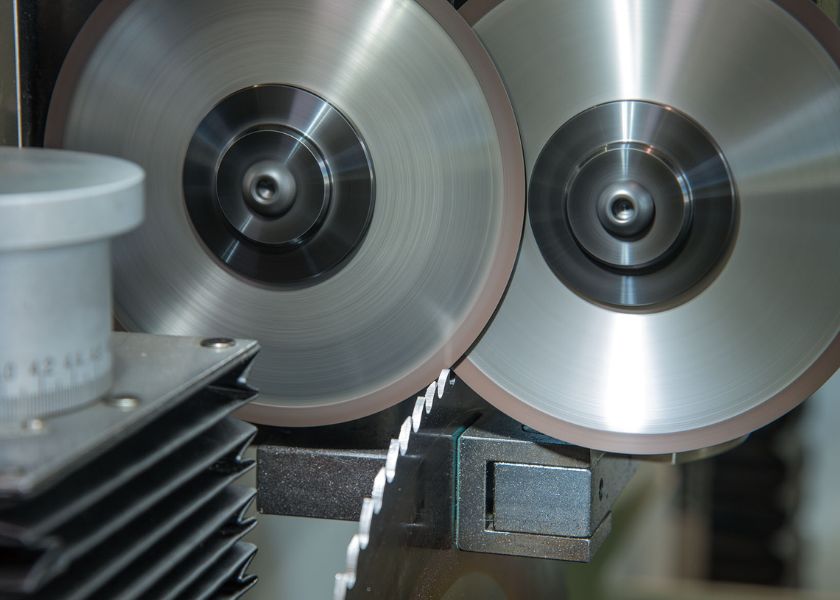

Vertical Chamfering machine for HSS saw blade. Circular saw blade outer diameter: Φ150-650mm. Quick clamp saw blade device using magnetic force to stable the blade. The blade will be ground simultaneously by two independently adjusted grinding wheels. Grinding speed is controlled by Frequency. more

Vertical Chip break machine, operator could handle it easily. Suitable for HSS saw blades and TCT saw blades. Circular saw blade outer diameter: Φ140-650mm. Quick clamp saw blade device using magnetic force to stable the blade.more

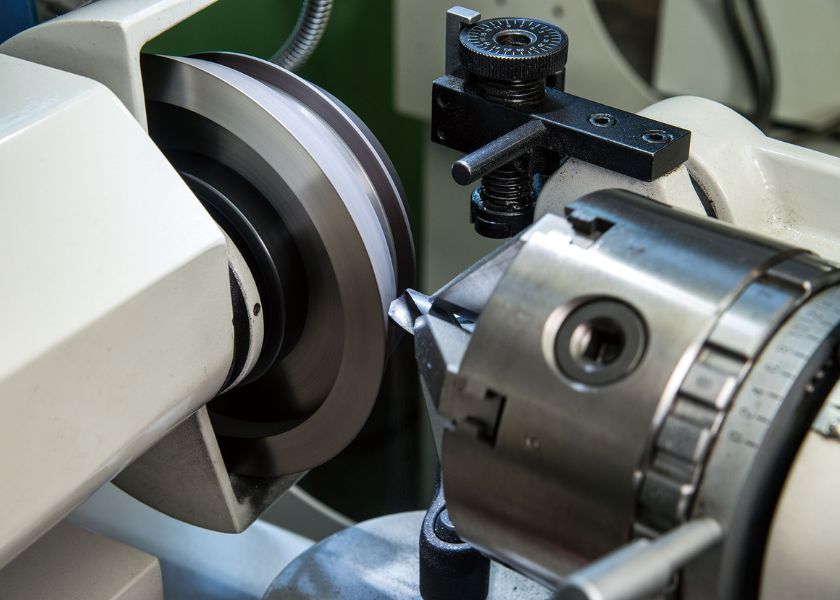

Manual Sharpening machine for sharpening HSS and solid carbide saw blade diameter up to 620mm. Chamfering function is equipped. Using inverter for grinding speed control increases the life-span of mechanism. Equipped with manual oil injector which is easy to lubricate the parts and maintain the machine in a good condition.more

Manual Sharpening machine for sharpening Friction saw blade diameter up to 1200mm. Using inverter for grinding speed control increases the life-span of mechanism. Equipped with manual oil injector which is easy to lubricate the parts and maintain the machine in a good condition.more

Drill grinding machine-Dry. Grinding range: Ø3 ~ Ø32mm. By changing the cam, drill, end mill cutter, chamfering cutter, tap, center drill and etc could be ground. Option Knife Edge Grinding Accessory, grinding outer diameter of end mill, side cutter, reamer, and drill bit. more

0

Manufacturing Since

0

+

Machine Sold

0

mm

Saw blade diameter up to